İSFALT has escalated its efforts, particularly as from 2004, in order to introduce the highest quality into the roads of İstanbul, and has thereupon become the center of quality and reliable knowledge in the asphalt sector.

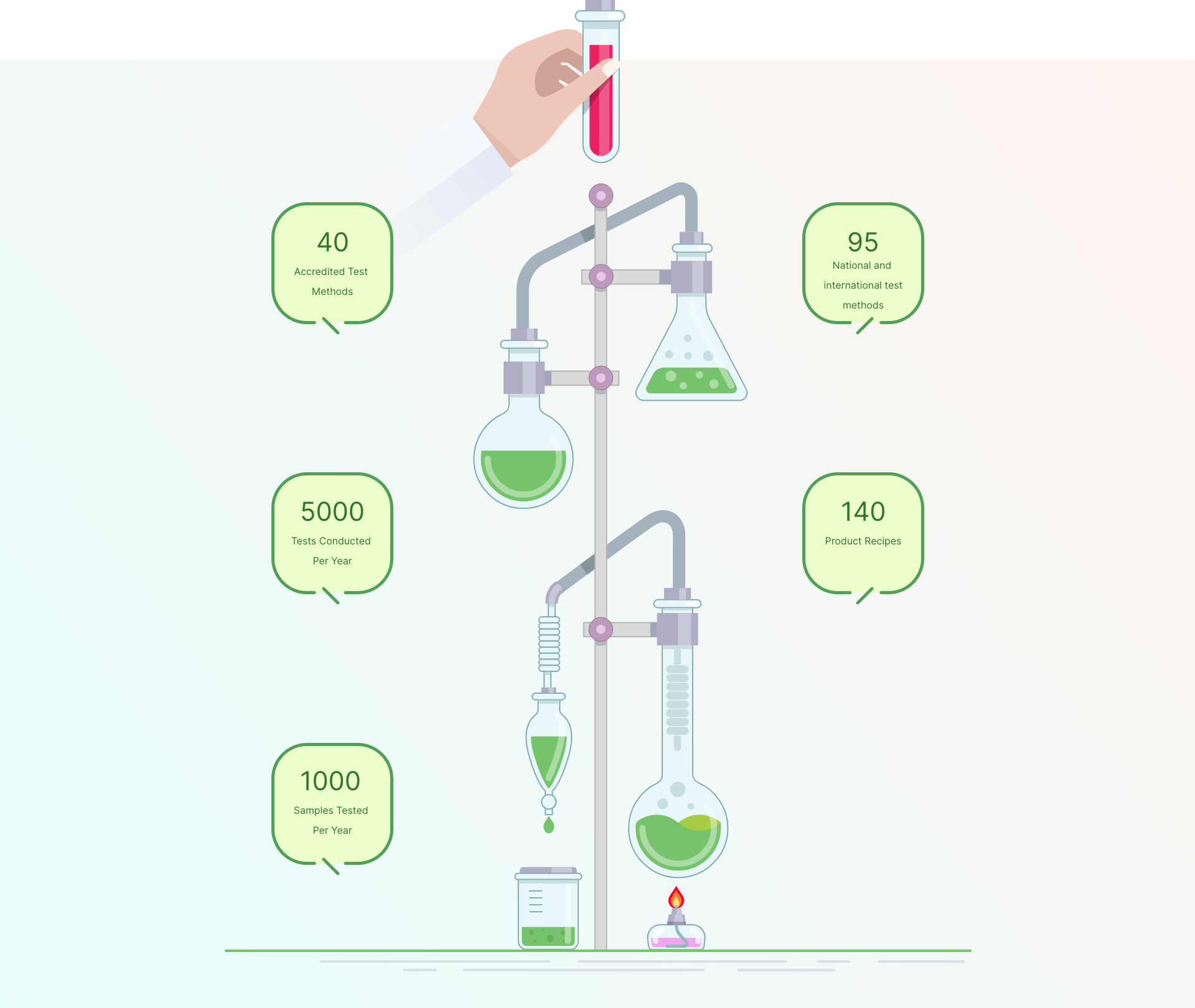

Having been resuming its R&D activities alongside its raw material and final product checks, İSFALT Laboratory has also been accredited by Turkish Accreditation Agency for 40 experiment methods. This makes İSFALT earned the title of being the asphalt company with a laboratory that is accredited for the highest number of experiments in Turkish asphalt sector.

Furthermore, it is capable of conducting product certification experiments as being the only laboratory holding TSE’s accreditation of “Experiment Service Provider Laboratory” in the field of asphalt experiments.

With 40 test methods accredited by the Turkish Accreditation Agency, ISFALT has the rank of "the accredited laboratory with the highest number of tests in the Turkish asphalt sector" and provides analysis services with international validity to public institutions, many domestic and foreign companies, with its advanced technology and accredited identity.

ISFALT has a "Laboratory Approved for TSE Test Service" certificate in accordance with the criteria of the Turkish Standards Institute (TSE) laboratory criteria for obtaining test service and other relevant TSE legislation. In this context, asphalt products are tested by competent and independent personnel and asphalt product certification and CE marking testing services are provided in accordance with international standards, in which the compliance of asphalt products with the relevant technical regulations is determined.

ISFALT Laboratory serves public institutions, private sector, and international companies with 95 test methods on internationally recognized subjects of aggregate, bitumen, emulsion, asphalt mixture and soil. A wide range of support is provided from national and international projects to the design process and testing services.

ISFALT Laboratory closely follows the technological developments in the world and carries out high-tech product development studies to meet the changing requirements of the asphalt sector. As a result of these efforts, new generation asphalt products such as recycled asphalt, warm mix asphalt, mastic asphalt and colored asphalt were added to the portfolio and the number of product prescriptions reached 140.

With the aim of increasing the quality and sustainability of asphalt roads, ISFALT uses digital technology and a dynamic management system focused on customer satisfaction to develop, monitor, and improve traditional processes. With its expert laboratory team, it incorporates the latest testing technologies that characterize the physical and rheological behavior of asphalt, implementing new composition designs that improve the performance of roads.

With its ability to perform all necessary quality control analyses, ISFALT Laboratory supports quality control activities, from the selection of raw materials used in asphalt products to production and application processes.